Devulcanized Crumb Rubber as Bitumen Modifier

DOI:

https://doi.org/10.24193/subbchem.2024.2.03Keywords:

crumb rubber, desulfurization, molybdenum catalystsAbstract

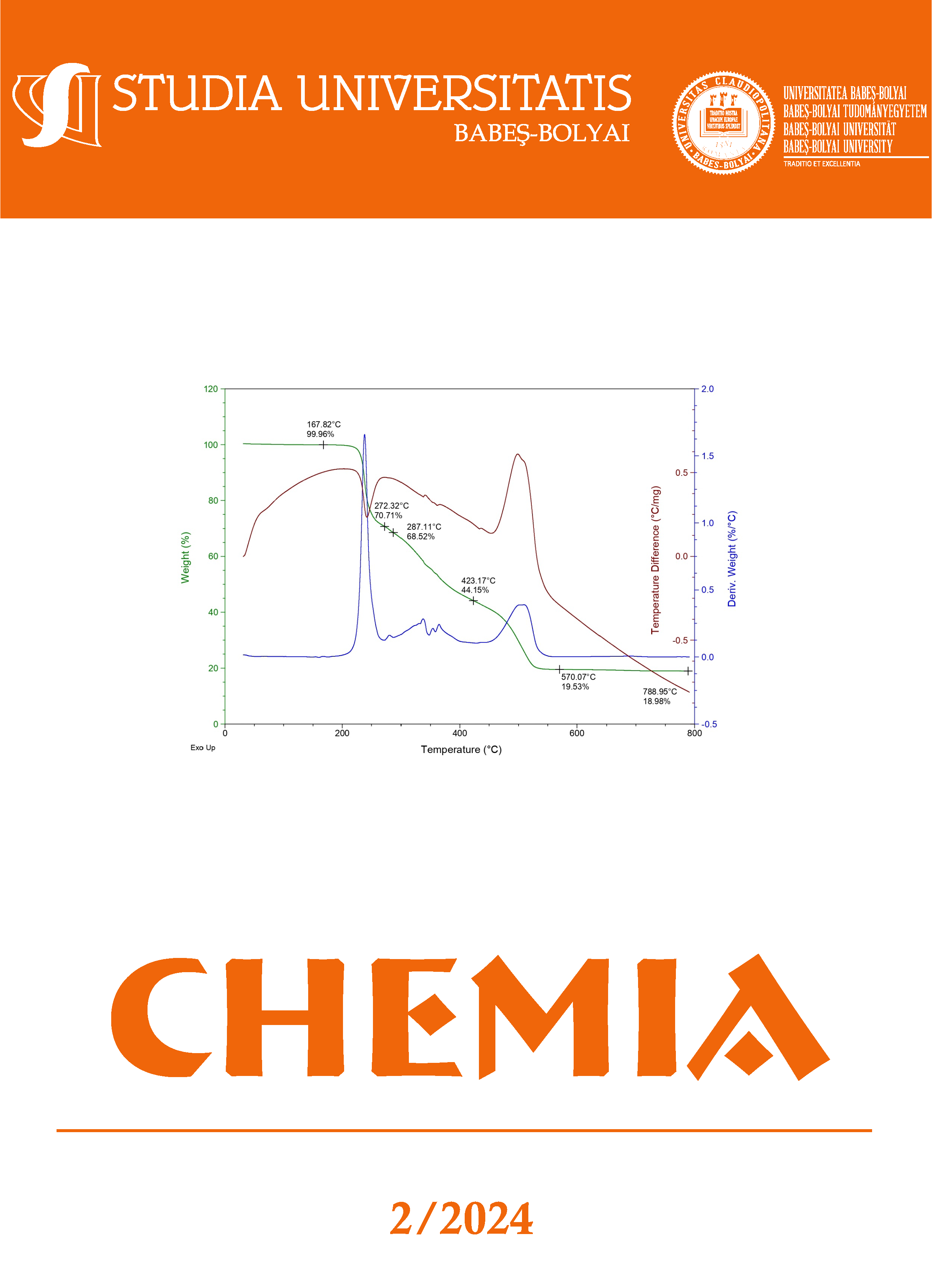

The dispersion of crumb rubber in road bitumen is essential for enhancing the elasticity of asphalt coatings. However, elastomer cross-linking through vulcanization can reduce the colloidal stability of bitumen. This study aims to enhance compatibility by partially devulcanizing crumb rubber using a pulverulent catalyst, specifically phosphomolybdic acid, in a batch reactor at 270°C. The use of a molybdenum-based catalyst is preferred due to its effectiveness in catalyzing the devulcanization process. Additionally, further conditioning of the catalyst through grinding optimizes contact with crumb rubber, enhancing catalyst activity and improving overall compatibility with road bitumen.References

A.M. Moasas; M. N. Amin; K. Khan; W. Ahmad; M. N. A. Al-Hashem; A. F. Deifalla; A. Ahmad; Case Stud in Constr Mat, 2022, 17, e01677.

J. Xu; M. Zheng; X. Ding; R. Qiao; W. Zhang; Constr. and Build Mat., 2023, 403, e 133204.

Z. Qi-sen; C. Yu-liang; L. Xue-lian; GeoHunan Intl. Conf., 2009.

M. Genever; K. O’Farrell; P.Randell; 2017, National market development strategy for used tyres 2017-2022, https://assets.sustainability.vic.gov.au/asset-download/Report-National-Market-Development-Strategy-Tyres-2018.pdf accessed nov. 2023.

D Lo Presti; Constr. Build. Mater., 2013, 49, 863–881.

S. Mostoni; P. Milana; B. Di Credico; M. D’Arienzo; R. Scotti; Catalysts, 2019, 9, 664.

A. A. da Silva; M. A. V. de Souza; A. M. F de Sousa; N. M. F. Carvalho; C. R. G. Furtado; J. Appl. Polym. Sci. 2024, 141(7).

L. Chen; Z.P. Hu; J.T. Ren; Z. Wang; Z.Y. Yuan; Microporous Mesoporous Mater., 2021, 315.

L.-A. Mirt; D. Bombos; S. Ghimiș; M.M. Bombos; G. Vasilievici; STUDIA UBB CHEMIA, LXVIII, 2023, 1, 225-238.

T. Yuming; L. Tenghui; Y. Guojia; W. Lui; T. La; Z. Zhiyong; R. Zhongqi; Energy & Fuels, 2019, 33 (9), 8503-8510.

F.J.P. Navarro; F. Partal; C. Martinez-Boza; C. Valencia; C. Gallegos; Chem. Eng. J., 2002, 89, 53–61.

B. Adhikari; D. De; S. Maiti; Prog. Polym. Sci., 2000, 2, 909–948.

L. Asaro; M. Gratton; S. Seghar; N. A. Hocine; Res. Cons. and Recycl., 2018, 133, 250-262.

I. Mangili; M. Lasagni; M. Anzano; E. Collina; V. Tatangelo; A. Franzetti; P. Caracino; A.I. Isayev; Polym. Degrad. Stab., 2015, 121, 369–377.

B. Adhikari; D. De; S. Maiti; Prog. Polym. Sci., 2000, 2, 909–948.

Mark; B. Erman; M. Roland; Recycling of Rubber, in The Science and Technology of Rubber, A.I. Isayev, Academic Press: Cambridge, MA, USA, 2013; pp. 697–764.

Q. Lv; W. Huang; M. Zheng; Y. Hu; C. Yan; J. Wang; Constr. and Build. Mat., 2022, 348,128716.

A. S. Mohamed; Z. Cao; X. Xu; F. Xiao; T. Abdel-Wahed; J. Clean. Prod., 2022, 373, 133896.

I. Gawel; R. Stepkowski; F. Czechowski; Ind. Eng. Chem. Res., 2006, 4, 3044–3049.

J.I. Gumede; B.G. Hlangothi, M. Briswell; C.D. Woolard; S.P. Hlangothi; J. Clean. Prod. 2022, 362.

T.C. Billiter, J.S. Chun; R.R. Davison; C.J. Glover; J.A. Bullin; Pet. Sci. Technol., 1997, 15, 445-469.

N. Herisanu; V. Bacria; Appl. Mech. Mater, 2013, 430, 257–261.

M. Liangş X. Xin; W. Fan; H. Luo; X. Wang; B. Xing; Constr. Build. Mater., 2015, 74, 235–240.

D. Lo Presti; Constr. Build. Mater., 2013, 49, 863–881.

D. Ion, M. Bombos, G. Vasilievici, A. Radu, P. Rosca, Rev.Chim. (Bucharest), 2019, 70, 4266-4274.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Studia Universitatis Babeș-Bolyai Chemia

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.