CHEMICALLY MODIFIED CHITOSAN COATINGS: WETTING AND ELECTROCHEMICAL STUDIES

DOI:

https://doi.org/10.24193/subbchem.2020.3.05Keywords:

chitosan coating, contact angles, electrochemical measurementsAbstract

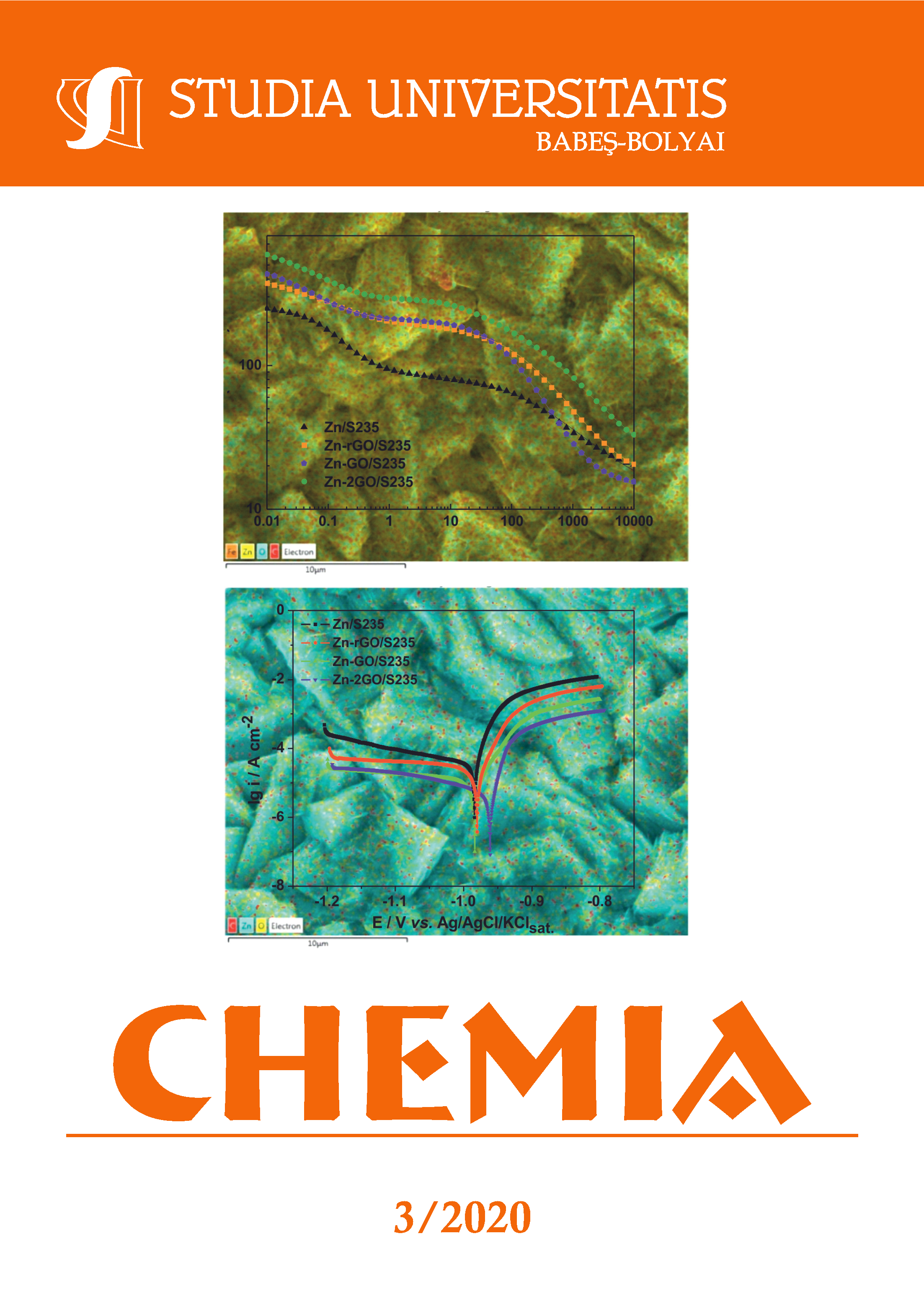

Native chitosan coatings were prepared on glass and zinc substrates by dip-coating method. The native coatings were chemically modified: crosslinked with glutaraldehyde and sodium-tripolyphosphate and then silylated with dichlorodimethylsilane. The native layers prepared on zinc substrate were acylated with acetic anhydride and impregnated with indigo carmine (IC). Native coatings on different substrates showed different morphology and physical structure, which were explored by AFM studies. Examining the wetting properties of the coatings, it was found that the chemical modification can form a stable, hydrophobic (advancing contact angle of ca. 97°) and water repellent (HΘ = 2°) layer on the glass substrate, while the same modifications reduce the hydrophobic nature and stability of the coating on zinc (contact angle decreases from ca. 100° to ca. 60°). Electrochemical studies of the coatings have shown that IC increases the corrosion protection (>90% inhibition efficiency) and reduces the permeability of the coating through ionic crosslinking, while acylation has the opposite effect and the acylated coating protection is worse than the native chitosan. The results can be used in the development of hydrophobic, water-repellent and temporary anti-corrosion coatings.

References

Z. Sebestyén, E. Jakab, A. Domán, P. Bokrossy, I. Bertóti, J. Madarász, K. László, J. Therm. Anal. Calorim. 2020, 1-8.

B. Duan, Y. Huang, A. Lu, L. Zhang, Prog. Polym. Sci. 2018, 82, 1–33.

S. Kumari, S.H. Kumar Annamareddy, S. Abanti, P. Kumar Rath, Int. J. Biol. Macromol. 2017, 104 1697–1705.

S. Tripathi, G.K. Mehrotra, P.K. Dutta, Int. J. Biol. Macromol. 2009, 45, 372–376.

T. Dai, M. Tanaka, Y.Y. Huang, M.R. Hamblin, Expert Rev. Anti. Infect. Ther. 2011, 9 857–879.

P.L. Kashyap, X. Xiang, P. Heiden, Int. J. Biol. Macromol. 2015, 77, 36–51

T. V. Podust, T. V. Kulik, B.B. Palyanytsya, V.M. Gun’Ko, A. Tóth, L. Mikhalovska, A. Menyhárd, K. László, Appl. Surf. Sci. 2014, 320, 563–569.

M. Dabóczi, E. Albert, E. Agócs, M. Kabai-Faix, Z. Hórvölgyi, Carbohydr. Polym, 2016, 136, 137–145.

C. Liu, Q. Bi, A. Leyland, A. Matthews, Corros. Sci. 2003, 45, 1257–1273

M.L. Zheludkevich, J. Tedim, C.S.R. Freire, S.C.M. Fernandes, S. Kallip, A. Lisenkov, A. Gandini, M.G.S. Ferreira, J. Mater. Chem. 2011, 21, 4805–4812.

Á.F. Szőke, G.S. Szabó, Z. Hórvölgyi, E. Albert, L. Gaina, L.M. Muresan, Carbohydr. Polym. 2019, 215, 63–72.

O. Lundvall, M. Gulppi, M.A. Paez, E. Gonzalez, J.H. Zagal, J. Pavez, G.E. Thompson, Surf. Coatings Technol. 2007, 201 5973–5978.

S.A. Umoren, M.J. Banera, T. Alonso-Garcia, C.A. Gervasi, M. V. Mirífico, Cellulose, 2013, 20 2529–2545.

Á.F. Szőke; G. Szabó; Z. Simó; Z. Hórvölgyi; E. Albert; A.G. Végh; L. Zimányi; L.M. Muresan; Eur. Polym. J., 2019, 118, 205–212.

J. Redepenning; G. Venkataraman; J. Chen; N. Stafford; J. Biomed. Mater. Res. - Part A., 2003, 66, 411–416.

J. Carneiro; J. Tedim; S.C.M. Fernandes; C.S.R. Freire; A. Gandini; M.G.S. Ferreira; M.L. Zheludkevich; ECS Electrochem. Lett., 2013, 2, C19.

K. Kurita, M. Hirakawa, S. Kikuchi, H. Yamanaka, J. Yang, Carbohydr. Polym. 2004, 56, 333–337.

A. Tiwari, J. Inorg. Organomet. Polym. Mater. 2009, 19, 361–366.

S. Höhne, R. Frenzel, A. Heppe, F. Simon, Biomacromolecules. 2007, 8, 2051–2058.

J. Xu, S.P. McCarthy, R.A. Gross, D.L. Kaplan, Macromolecules. 1996, 29, 3436–3440.

K.Y. Lee, W.S. Ha, W.H. Park, Biomaterials. 1995, 16, 1211–1216.

Z. Ye, X. Zhao, J. Microsc. 2010, 238, 27–35.

Z. Hórvölgyi, M. Máté, M. Zrínyi, Colloids Surfaces A Physicochem. Eng. Asp. 1994, 84, 207–216.

E. Bormashenko, Colloids Surfaces A Physicochem. Eng. Asp. 2008, 324, 47–50.

B. Matthes, E. Broszeit, J. Aromaa, H. Ronkainen, S.P. Hannula, A. Leyland, A. Matthews, Surf. Coatings Technol. 1991, 49, 489–495.

E. Hild, A. Deák, L. Naszályi, Ö. Sepsi, N. Ábrahám, Z. Hórvölgyi, J. Opt. A Pure Appl. Opt. 2007, 9, 920–930.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Studia Universitatis Babeș-Bolyai Chemia

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.