CORROSION RESISTANCE OF CERIUM-CONVERSION COATINGS FORMED FROM CERIUM(III) SALTS ON ALUMINIUM ALLOY 7075-T6

DOI:

https://doi.org/10.24193/subbchem.2020.3.18Keywords:

aluminium alloy 7075-T6, corrosion, cerium conversion coatings, cerium saltsAbstract

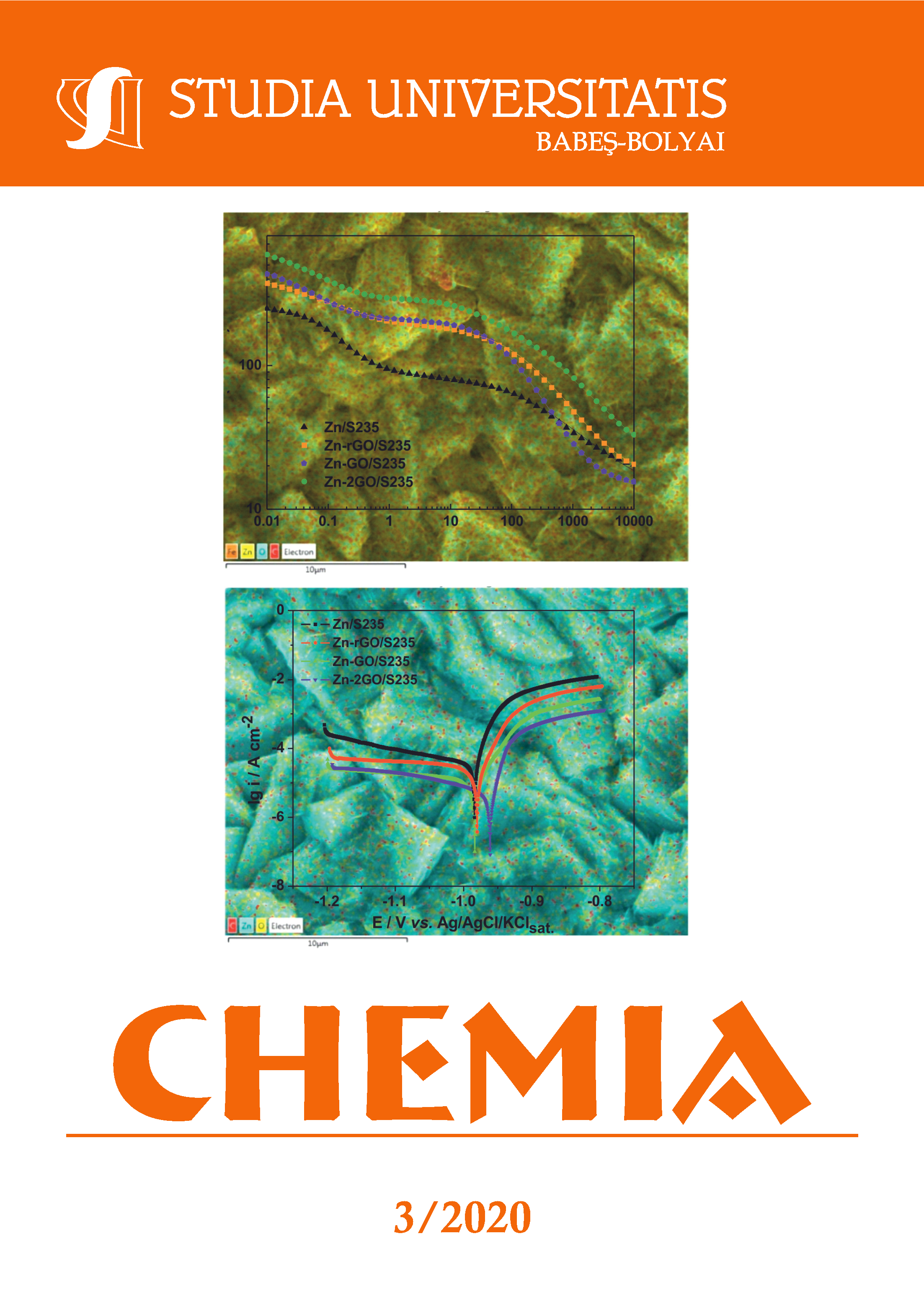

Cerium conversion coatings were explored as an alternative to chromate conversion coatings for corrosion protection of aluminium alloy 7075-T6. Conversion coatings were formed in a conversion bath of 0.05 M cerium salt and 0.25 M hydrogen peroxide at room temperature. Various cerium salts were used: Ce(III) acetate, Ce(III) nitrate and Ce(III) chloride. The conversion process from Ce3+ to Ce4+ was followed by UV-VIS spectroscopy. The conversion of cerium coatings on alloy surface was monitored by measuring open circuit potential. To investigate the corrosion properties of uncoated and coated samples, the linear polarization and electrochemical potentiodynamic curves were recorded in 0.1 M NaCl. Additionally, salt spray chamber testing was carried out. Samples were characterized by scanning electron microscopy. Results revealed that the cerium conversion and corrosion resistance were dependent on the type of cerium salt and conversion time in the conversion bath. The most compact and uniform cerium conversion coatings were produced from solution of cerium (III) acetate, but better protection was obtained in nitrate and, especially, chloride solutions due to thicker coatings.

References

J.E. Hatch, Aluminum: Properties and Physical Metallurgy, ASM International, 1984.

J.R. Davis, Corrosion of Aluminum and Aluminum Alloys, ASM International, 1999.

P.L. Hagans; C.M. Haas; Surf. Eng. 1994, 5, 405–411.

M. Kendig; S. Jeanjaquet; R. Addison; J. Waldrop; Surf. Coat. Technol., 2001, 140, 58–66.

ECHA European Chemicals Agency, Chromium VI compounds - ANNEX XVII TO REACH - Conditions of restrictions, https://echa.europa.eu.

I. Milošev; Acta Chim. Slov., 2019, 66, 511–533.

O. Gharbi; S. Thomas; C. Smith; N. Birbilis; Npj Mater. Degrad., 2018, 12, 1–8.

B.R.W. Hinton, D.R. Arnott, N.E. Ryan; Met. Forum, 1984, 7, 211–217.

B. Hinton; Corrosion, 2010, 66, 085001-085001–15.

F.H. Scholes; C. Soste; A.E. Hughes; S.G. Hardin; P.R. Curtis; Appl. Surf. Sci., 2006, 253, 1770–1780.

M. Forsyth; B. Hinton; Rare Earth-Based Corrosion Inhibitors, Elsevier, 2014.

C.-S. Lin; W.-J. Li; Mater. Trans., 2006, 47, 1020–1025.

A. Decroly; J.-P. Petitjean; Surf. Coat. Technol., 2005, 194, 1–9.

M. Dabalà; L. Armelao; A. Buchberger; I. Calliari; Appl. Surf. Sci. 2001, 172, 312–322.

T.G. Harvey; Corros. Eng. Sci. Technol., 2013, 48, 248–269.

P. Rodič; I. Milošev; J. Electrochem. Soc. 2016, 163, C85–C93.

I. Milošev; P. Rodič; Corrosion, 2016, 72, 1021–1034.

B. Volarič; I. Milošev; Corros. Eng. Sci. Technol., 2017, 52, 201–211.

P. Rodič; I. Milošev; Corros. Sci. 2019, 149, 108–122.

P. Rodič; I. Milošev; M. Lekka; F. Andreatta; L. Fedrizzi; Electrochim. Acta. 2019, 308, 337–349.

I. Milošev; B. Volarič; Corrosion, 2017, 73, 822–843.

B. Volarič; A. Mazare; S. Virtanen; I. Milošev; Corrosion, 2020, 76, 18–38.

F. Andreatta; M.M. Lohrengel; H. Terryn; J.H.W. de Wit; Electrochim. Acta, 2003, 68, 3239–3247.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2020 Studia Universitatis Babeș-Bolyai Chemia

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.