BEHAVIOR IN AC POLARIZATION OF HIGH-SILICON CAST IRONS

DOI:

https://doi.org/10.24193/subbchem.2021.1.04Keywords:

silicon cast iron, corrosion, AC polarization, mass loss, inert anodes.Abstract

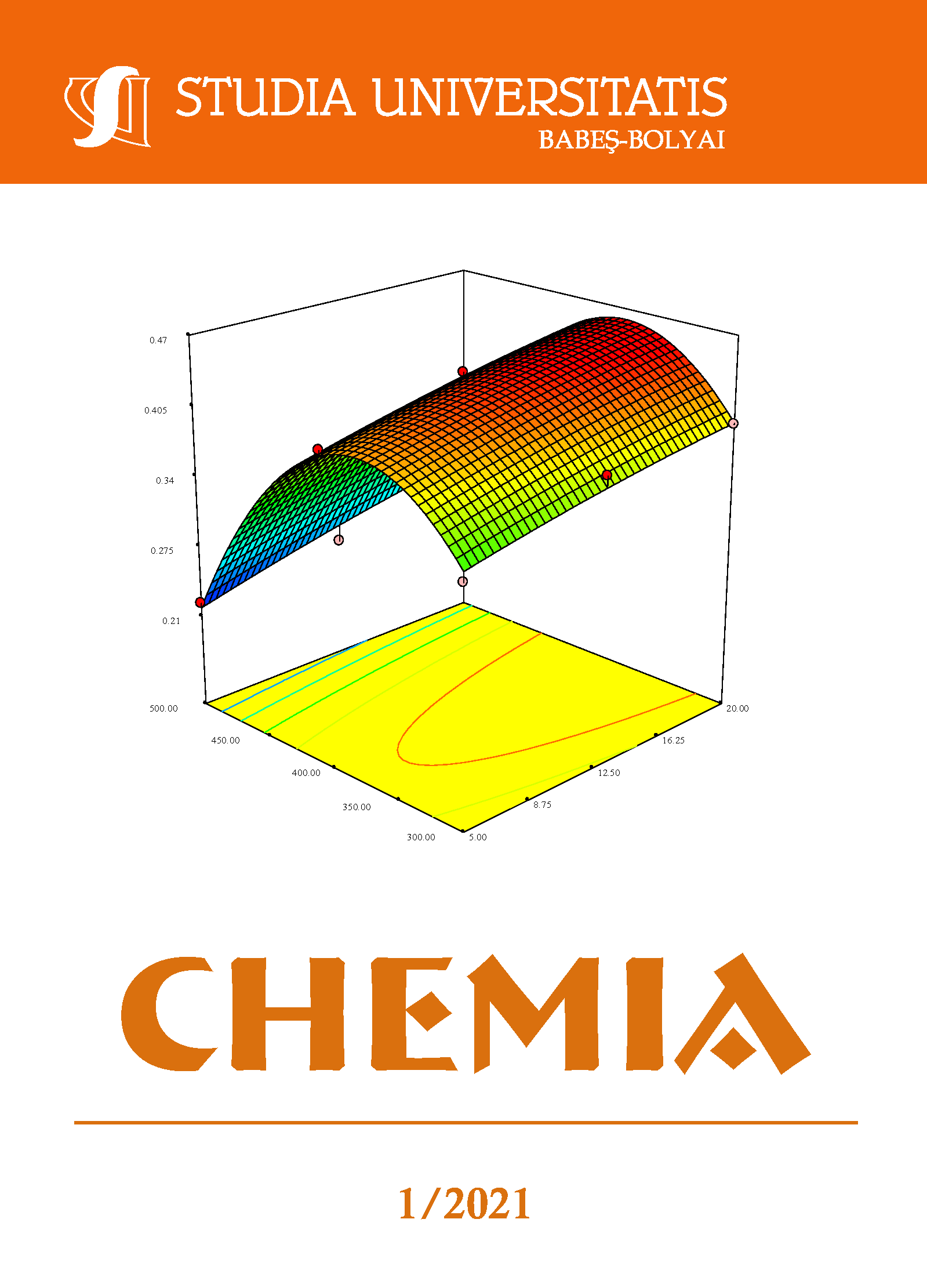

The behavior of high-silicon cast irons in AC polarization was studied in terms of elementary composition and morphological structure to find suitable materials for inert anodes used in various electrochemical processes with polarization in AC or DC with superimposed AC signal. Experimentally, through optical emission spectrometry, XRD, and SEM-EDAX techniques, the investigated samples' morphology and composition were determined. The behavior in AC polarization at Jac current density between 1 and 300 A/m2 was assessed through electrochemical and gravimetric methods. The results showed that the mass losses in AC polarization at Jac less than 10 A/m2 are insignificant (below 8.5x10-5 g/Ah), and at Jac 100 A/m2, samples with a Si content higher than 8% were below 3.75x10–4 g/Ah (approx. 150x less than in the case of similar anodically polarized materials in DC). It was also noted that the main processes that occur in the AC polarization of silicone cast iron in aqueous media consist of the anodic oxidation of iron with the formation of iron oxide films and the anodic dissolution with the formation of soluble compounds of some metals from the composition of silicone cast irons (Mn, Cr, Cu, etc.). Furthermore, these anodic processes are coupled with the cathodic processes, which in natural environments consist most probably in reducing the dissolved oxygen.

References

A. Świercz; E. Zajęcka; Carpathian J. Earth Environ. Sci., 2018, 13 (1), 249-266.

G.M. Ispas; C. Roba; R. Bâlc; D.M. Gligor; Carpathian J. Earth Environ. Sci., 2020, 15 (2), 415–428.

M.R. Niță; C.I. Ioja; Carpathian J. Earth Environ. Sci., 2020, 15 (2), 471–479.

E.A. Stere; I. Popa; Electroteh. Electron. Autom., 2018, 66 (4), 127-134.

T. Erdey-Grúz; Kinetics of electrode processes, Akadémiai kiadó, Budapest, Hungary, 1969, pp. 15-45.

Y. Xianjin; Z. Lipeng; D. Yunhui; Z. Zengdian; J. Rare Earths, 2006, 24 (1), 352-354.

F. Zaza; C. Paoletti; R. Lo-Presti; E. Simonetti; M. Pasquali; J. Power Sources, 2010, 195 (13), 4043-4050.

R.D. Xu; L.P. Huang; J.F. Zhou; P. Zhan; Y.Y. Guan; Y. Kong; Hydrometallurgy, 2012, 125–126, 8-15.

W. Yun-Hai; C. Qing-Yun; L. Guo; L. Xiang-Lin; Anodic materials with high energy efficiency for electrochemical oxidation of toxic organics in waste water, in: Industrial waste, K. Y. Show, X. Guo Eds; IntechOpen, Rijeka, Croatia, 2012, Chapter 2, pp. 33-50

I. Gallino; M.E. Kassner; R. Busch; Corros. Sci., 2012, 63, 293-303.

D. Jia; K. Wang; J. Huang; Chem. Eng. J., 2017, 317, 673-686.

H. Chu; Q. Wu; J. Huang; Colloids Surf. A Physicochem. Eng. Asp., 2018, 558, 495-503.

S. Permeh; K. Lau; M.E. Boan; B. Tansel; M. Duncan; J. Mater. Civ. Eng., 2020, 32 (7), 04020184.

O.G. Kuznetsova; A.M. Levin; O.I. Tsybin; M.A. Sevostyanov; V.A. Bryukvin; A.O. Bolshikh; Russ. Metall., 2018, 2018 (7), 651–654.

K.V. Hansen; M. Chen; T. Jacobsen; K.T.S. Thydén; S.B. Simonsen; S. Koch; M.B. Mogensen; J. Electrochem. Soc., 2016, 163 (10), 1217- 1227.

S. Geißler; H. Tiainen; H.J. Haugen; Mater. Sci. Eng. C., 2016, 63, 359-366.

I. Lingvay; C. Homan; C. Lingvay; Rev. Chim., 2007, 58 (11), 1051-1054.

I. Lingvay; A. Voina; C. Lingvay; C. Mateescu; Rev. Roum. Sci. Techn.– Électrotechn. Énerg, 2008, 53 (2), 95-112.

I. Lingvay; A.M. Bors; D. Lingvay; L. Radermacher; V. Neagu; Rev. Chim., 2018, 69 (12), 3593-3599.

D. Sandu; I. Lingvay; S. Lányi; D.D. Micu; C.L. Popescu; J. Brem; L.C. Bencze; C. Paizs; Studia UBB Chemia, 2009, 54 (4), 195-201.

R.W. Hunt; A. Zavalin; A. Bhatnagar; S. Chinnasamy; K.C. Das; Int. J. Mol. Sci., 2009, 10, 4515-4558.

M. Gao; J. Zhang; H. Fen; Bioelectromagnetics, 2011, 32, 73-78.

C. Stancu; M. Lingvay; I. Szatmári; I. Lingvay; The 8th Int. Symp.on ATEE, Bucharest, Romania, May 23-25, 2013, 1-4.

E. Radu; D. Lipcinski; N. Tănase; I. Lingvay; Electroteh. Electron. Autom., 2015, 63 (3), 68-74.

M. Lingvay; A.R. Caramitu; A.M. Bors; I. Lingvay; Studia UBB Chemia, 2019, 64 (2), 279-288.

C. Mateescu; I. Lingvay; A. Caramitu; N. Tanase; E. Radu, RO Patent RO132199 B1, 2020.

C. Bartha; A. Caramitu; M. Jipa; D.M. Ignat; A. Tókos; Studia UBB Chemia, 2020, 65 (4), 85-93.

C. Bartha; M. Jipa; A.R. Caramitu; A. Voina; A. Tókos; D.M. Ignat; I. Lingvay; Rev. Roum. Sci. Techn.– Électrotechn. Énerg, 2020, in press

M. Stawarz; W. Kajzer; A. Kajzer; M. Dojka; Arch. Foundry Eng., 2017, 17 (2), 101-106.

U. de la Torre; A. Loizaga; J. Lacaze; J. Sertucha; J. Mater. Sci. Technol., 2014, 30 (12), 1425-1431.

Specialist Castings Limited; High Silicon Cast Iron Anode, (n.d.).

I. Lingvay; C. Lingvay; G. Rus; I. Laţa; V. Pavlovschi; L. Ancas; RO Patent 120717 B1, 2001.

R. González-Martínez; U. de la Torre; J. Lacaze; J. Sertucha; Mater. Sci. Eng. A, 2018, 712, 794- 802.

P. Rubin; R. Larker; E. Navara; M.L. Antti; Metallogr. Microstruct. Anal., 2018, 7, 587–595.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2021 Studia Universitatis Babeș-Bolyai Chemia

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.