SYNTHESIS OF HYDROCARBON FUELS VIA SELECTIVE REFORMING OF KEROSENE OVER VARIOUS NI/ZEOLITE CATALYSTS

DOI:

https://doi.org/10.24193/subbchem.2021.4.14Keywords:

Reforming process, Bi-functional catalysts, Zeolite, Kerosene, Jet fuel, Reaction pathway.Abstract

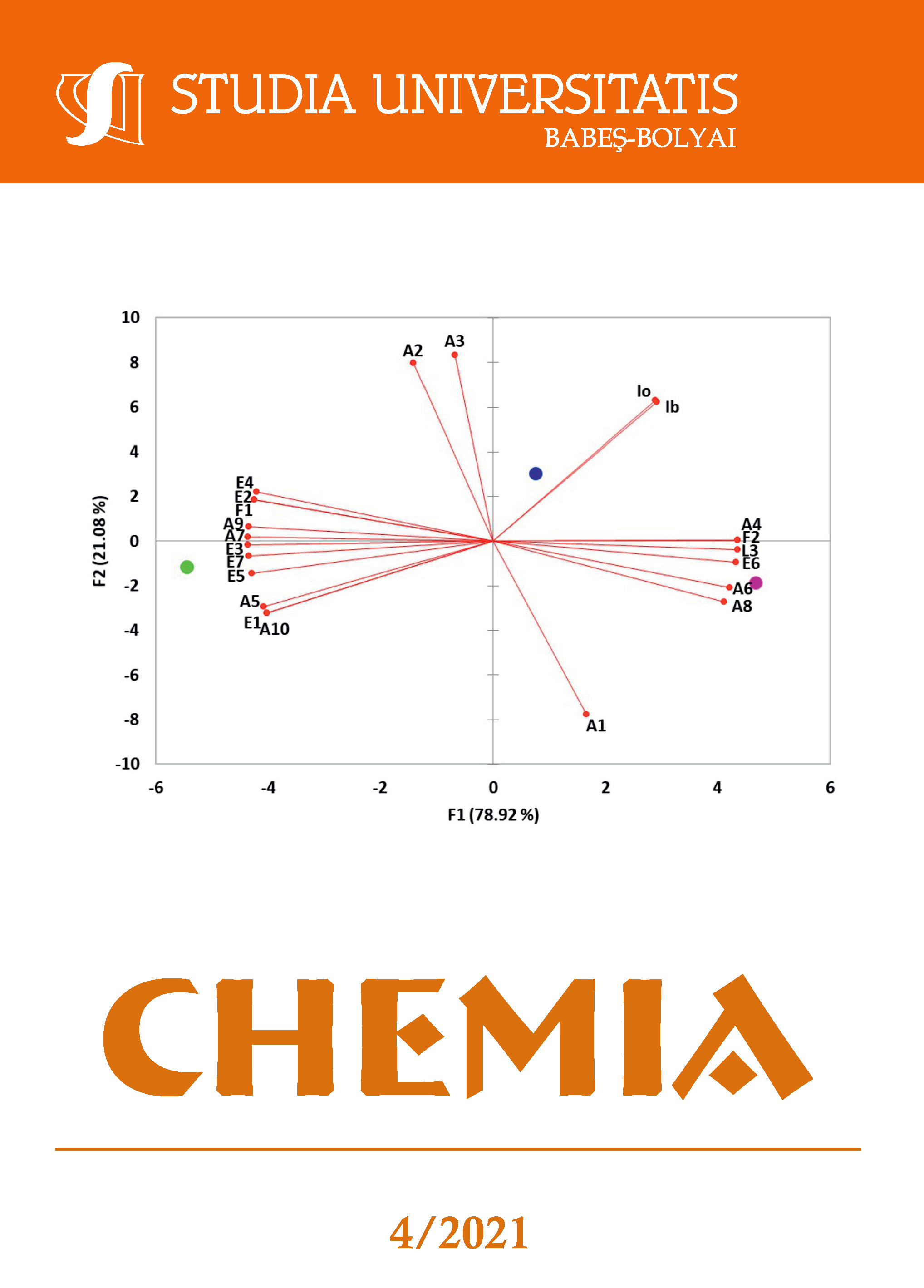

In this study, the reforming of kerosene was performed in a fixed-bed reactor in order to investigate the synthesis of hydrocarbon fuels. For this purpose, five Ni-based catalysts supported on Y, Mordenite, ZSM-5, Beta, and Ferririte zeolites were prepared by deposition-precipitation method. Four main composition groups of hydrocarbons including normal paraffins, isoparaffins, cycloparaffins, and aromatics were analyzed in feed and liquid products and the effects of key parameters of the catalysts namely acidity, diameter of pores in channels, and surface area on the progress of the reforming process were surveyed. According to the analysis results, Y zeolite with higher acidity, larger pore diameter, and more surface area led to produce the most aromatic contents (57.60%) in the products. Beta increased both cycloparaffins (34.91%) and isoparaffins (34.07%) in the product. Mordenite and Ferririte effectively increased the formation of isoparaffins by 38.22% and 38.85% respectively. Meanwhile, ZSM-5 with moderate acidity, surface area, and pore size increased the cycloparaffin contents of the product (46.28%). These results highlighted the potential of each zeolite to produce a valuable product via reforming process, which meets the requirement of standard hydrocarbon fuels. Ultimately, the pathway to reforming process over each prepared catalyst was proposed.References

Global Energy & CO2 Status Report; International Energy Agency (IEA): Paris, France, 2018.

J.C. Serrano-Ruiz; J.A. Dumesic; Energy Env. Sci., 2011, 4, 83–99.

M. A. Díaz-Pérez; J. C. Serrano-Ruiz; Molecules, 2020, 25, 802-820.

S. Toamasek; Z. Varga; J. Hancsók; Fuel Process. Technol., 2020, 197, 106197. https://doi.org/10.1016/j.fuproc.2019.106197

J.D. Woodroffe; B. G. Harvey; energy fuels, 2020, https://dx.doi.org/10.1021/acs.energyfuels.0c00274

F. Zaera; Appl. Catal. A., 2002, 229, 75–91.

A. Klerk; Molecules, 2018, 23, 115-126.

M. Shahabuddin; M.T. Alam; B.B. Krishn; T. Bhaskar; G. Perkins; Bior Tech., 2020, 312, 123596.

T.K. Habibie; B. H. Susanto; M. F. Carli; E3S Web of Conferences 67, 2018.

S. Tomasek; Z. Varga; J. Hancsók; Fuel Process. Technol., 2020, 197, 106197.

H. Wang; S. Yan; M. Kim; S.O. Salley; K.Y.S. Ng; Current Catalysis, 2012, 1, 132-139.

X. Li; A.A. Alwakwak; F. Rezaei; A.A. Rownaghi; ACS Appl. Energy Mater., 2018, 1 (6), 2740–2748.

G.J. Antos; A.M. Aitani; Catalytic Naphtha Reforming, 2nd ed., Marcel Dekker, New York, 2004, pp. 335–349.

C.E. Xu; Catalytic Reforming Process and Engineering, China Petrochemical Press, Beijing, 2006, pp. 1–26.

P. Zhang; Y. Yang; Z. Li; B. Liu; C. Hu; Catal. Today, 2019, https://doi.org/10.1016/j.cattod.2019.07.032.

M. Shahinuzzamana; Z. Yaakob; Y. Ahmed; Renew. Sust. Energ. Rev., 2017, http://dx.doi.org/10.1016/j.rser.2017.01.162.

J. Y. Kim; J. Moon; J.H. Lee; X. Jin; J.W. Choi; Fuel, 2020, 279, 118484.

F. Thomas; J. Degnan; Top Catal., 2020, 13, 349–356.

A. Ishihara; Fuel Process Technol., 2019, 194, 106-116.

W. Namchota; S. Jitkarnka; J Anal Appl Pyrolysis., 2016, 118, 86–97.

H. Kim; D. Kim; Y. K. Park; J. K. Jeon; Res Chem Intermed, 2018, 44, 3823–3833.

D. Yao; H. Yang; H. Chena; P.T. Williams, Appl. Catal. B Environ., 2018, 227, 477- 487.

X. Yang; J. Da; H. Yu; H. Wang; Fuel, 2016, 179, 353–361.

L. Liu; L. Hong; AIChE Journal, 2011, 57, 3143-3152.

A.J. Maia; B. Louis; Y.L. Lam; M.M. Pereira; J. Catal., 2010, 269 (1), 103-109.

M. Lallemand; O.A. Rusu; E. Dumitriu; A. Finiels; F. Fajula; V. Hulea; Appl. Catal. A., 2008, 338, 37-43.

L. Chen; X. Wang, H. Guo; X. Guo; Y. Wang; H. Liu; G. Li, Catal. Commun., 2007, 8, 416–423.

P. Yan; J. Mensah; A. Adesina; E. Kennedy; M. Stockenhuber; Appl. Catal. B Environ., 2020, 267, 118690.

A. Marcilla; A. Gómez-Siurana; F. Valdés; J. Anal. Appl. Pyrolysis, 2007, 79, 433-442.

A. Kant; Y. He; A. Jawad; X. Li; F. Rezaei; J.D. Smith; A. A. Rownaghi; Chem. Eng. J., 2017, 317, 1-8.

M. A. Atanga, F. Rezaei, A. Jawad, M. Fitch, A. A. Rownaghi, Appl. Catal. B Environ., 2018, 220, 429-445.

S. C. Qi; X. Y. Wei; Z. M. Zong; J. Hayashi; X. H. Yuan; L. B. Sun; Chem Cat Chem., 2013, 5, 3543-3547.

K.B. Golubev; K. Zhang; X. Su; N.V. Kolesnichenko; W. Wu; Catal Commun., 2021, 149, 106176.

T. K. Habibie; B.H.Susanto; M. F. Carli; E3S Web of Conferences 67, 02024, 2018, 3rd i-TREC 2018.

M.Y. Choo; L. E. Oi; T. J. Daou; T. C. Ling; Y.C. Lin; G. Centi; E. P. Ng; J. C. Juan; Materials, 2020, 13, 3104.

X. Zou; X. Wang; L. Li; K. Shen; X. Lu; W. Ding; Int J Hydrog Energy, 2010, 35, 12191- 12200.

A. Ishihara; R. Ishida; T. Ogiyama; H. Nasu, T. Hashimoto, Fuel Process. Technol., 2017, 161,17–22.

R. Nishu; M. Liu; M. Rahman; M. Sarker, M. Chai; C. Li; J. Cai; Fuel Process. Technol., 2020, https://doi.org/10.1016/j.fuproc.2019.106301.

S. Zulkepli; J.C. Juan; H.V. Lee; N.S.A. Rahman; P.L. Show; E.P. Ng; Energy Convers. Manag., 2018, 165, 495–508.

C. Wang; Q. Liu; J. Song; W. Li; P. Li; R. Xu; H. Ma; Z. Tian, Catal. Today, 2014, 234, 153-160.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2021 Studia Universitatis Babeș-Bolyai Chemia

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.